Benefits:

Low Coefficient of Friction

Proven Product with over 50 years of service

Custom-designed to your application’s requirements

Manufactured in America

Design Data:

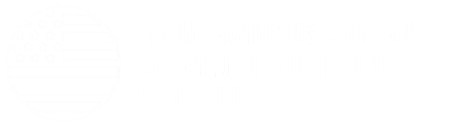

Loading Range: 75 to 3,500psi

Temperature Range: -320° to +400°F

Coefficient of friction: 0.10 to 0.04 (See below)

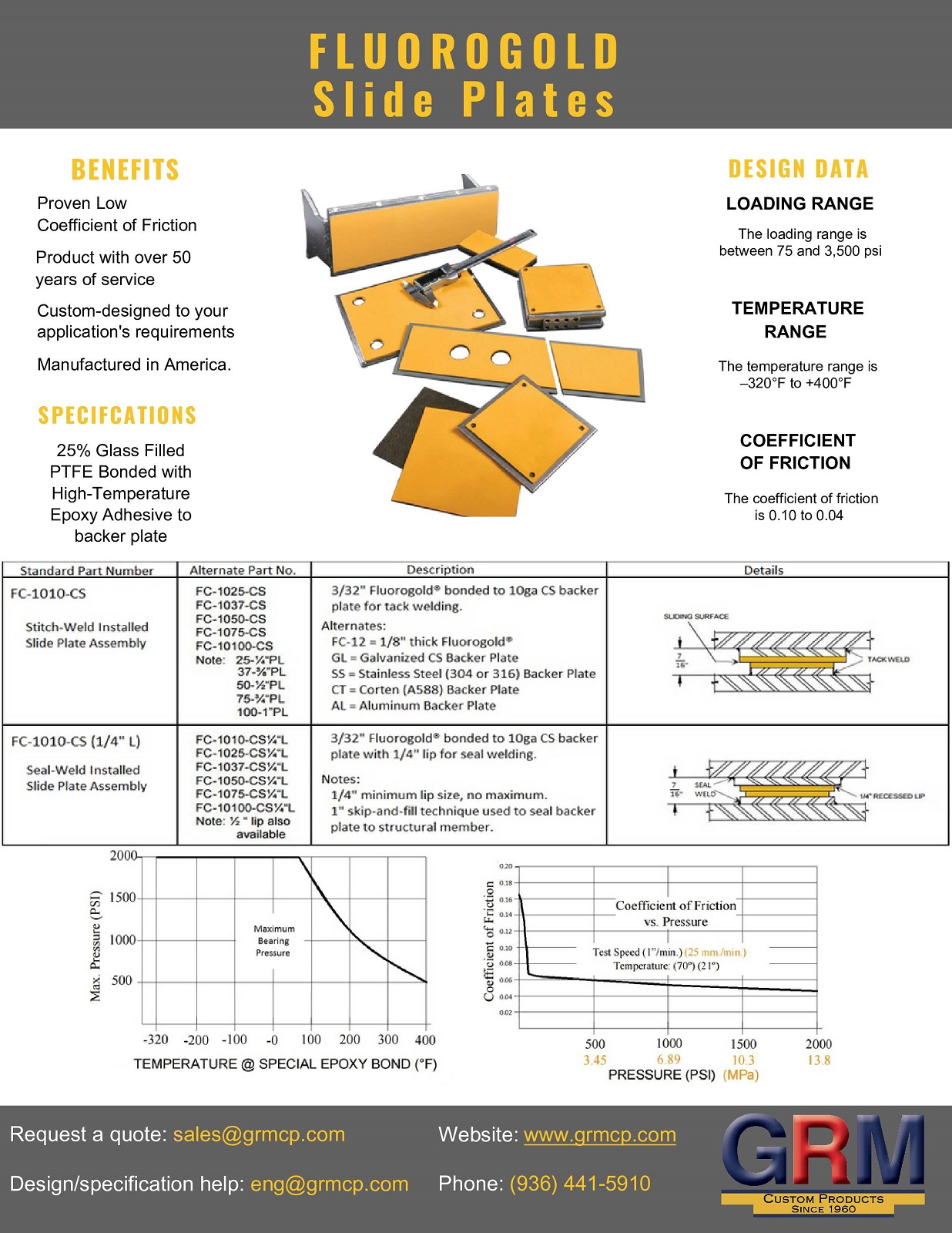

Specifications:

25% Glass Filled PTFE Bonded with High-Temperature Epoxy Adhesive to backer plate

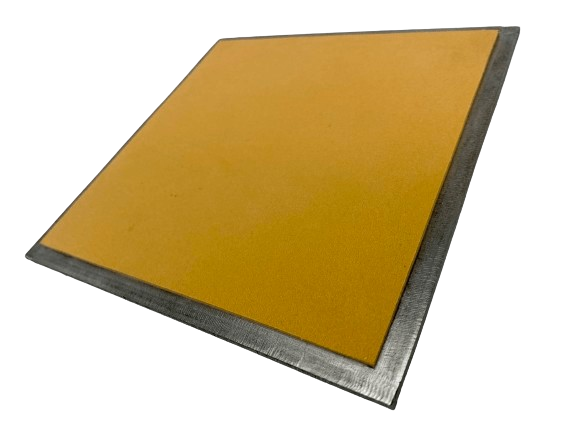

FLUOROGOLD® SLIDE PLATE BEARINGS

FLUOROGOLD® slide bearings systems are engineered products of GRM Custom Products in Conroe, TX. They fill the need for simple and economical structural supports by allowing simultaneously for thermal, seismic and mechanical expansions and contractions. These systems operate with the lowest coefficient of friction over a broad range of temperatures.

FLUOROGOLD® is comprised of virgin PTFE (often referred to as Teflon™, registered Trademark of the Chemours Company) combined with special reinforcing agents. This blend yields a structural material that offers significantly higher mechanical properties than PTFE itself. Compressive creep is virtually eliminated, wear is substantially reduced, and initial deformation is decreased. However, the low friction and chemical inertness of PTFE are still retained.

This structural bearing surface is bonded to a back-up steel plate with a high temperature homogenous epoxy system that is cured under precise heat and pressure in hydraulic presses. All FLUOROGOLD® bearings are factory bonded using strictly controlled, semi-automated procedures, developed to eliminate poor quality field-made bonds. FLUOROGOLD® bearings can be obtained with elastomeric back-up which will enable the system to accept live-load rotations.

In all cases, a slide bearing system is composed of two elements. The upper element, with its FLUOROGOLD® face down, mates with the lower element with its FLUOROGOLD® face up. The system is normally designed so that the upper element is larger than the lower element by the dimension of the anticipated motion so that the lower element is under uniform load throughout movement and so that foreign matter will not collect on the lower element.

The maximum design pressure of FLUOROGOLD® Slide Bearings, without elastomeric backing is 2000psi (see pressure vs. temperature chart for specific design criteria). For neoprene backed bearings the maximum recommended pressure is 800psi (5.5MPa) and for the cotton duck reinforced elastomer it is 1500 psi (10.3MPa).

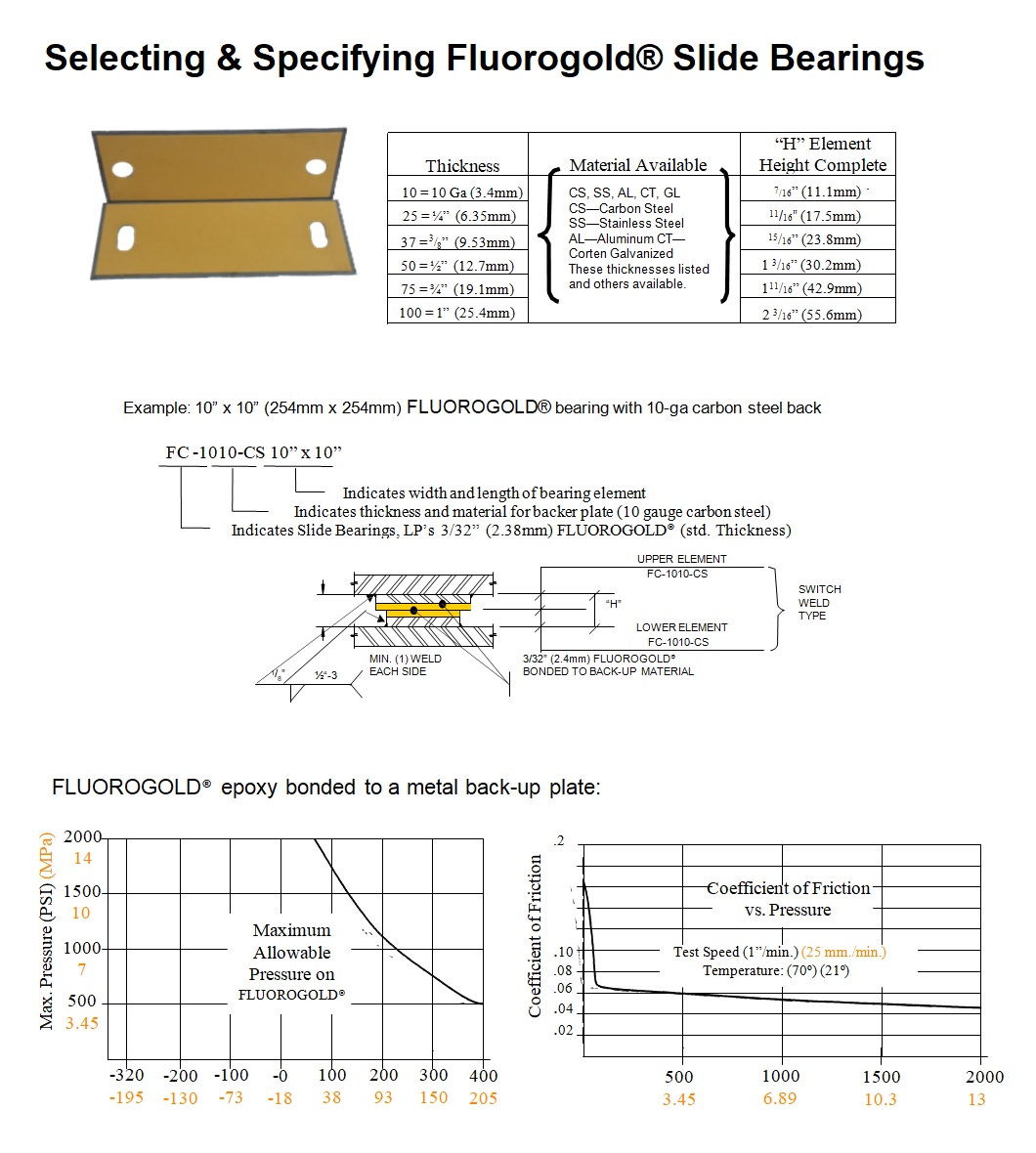

Selecting & Specifying Fluorogold® Slide Bearings

Selecting & Specifying Fluorogold® Slide Bearings

FLUOROGOLD® slide bearings are available in a variety of constructions to meet your specific requirements. Varying elements are the back-up plate material and thickness, and the construction for installation. If the element is to be continuously welded, the FLUOROGOLD® must be recessed (or lipped, ¼” minimum) on each of those sides This recess is not necessary for stitch welds. This recess is specified by the letter “L” in the callout and may be restricted to the short sides only or the long sides only by use of the appropriate letters (L-recess all sides, LSO-recess short side only, LLO-recess long side only). These variable elements must be specified in the callout.

Fluorogold® Applications

Fluorogold® Slide Plates Bearings

Architectural

- Building Separations

- Mullion Facades

- Mutual Bearing Walls

- Roof Slabs

- Seismic Separations

- Loading Docks

- Skyways

- Beams and Joists

- Concrete Beam and Haunch

- Airport Hangar Doors

- Concrete Parking/Ramps

- Girder Slip Joints

Petrochemical

- Pipe Slides

- Boilers

- Heat Exchangers

- Distillation Towers

- Pressure Vessels

- Pipe Hangers

- Cryogenic Supports

- Storage Tanks

- Air Preheaters

- Frac Towers

Industrial Equipment

- Conveyors

- Dust Collectors

- Cranes

- Heavy Machinery

- Slides

- Vibration Pads

- Material Handling

- Antenna Towers

Bridges

- Post-tension & Box Girders

- Pedestrian Bridges

- Highway and Railway Bridges

- Cast in Place

- Roadway Expansion Joints

Marine

- Wharfs & Docks

- Wedge Blocks

- Cargo Slides

- Trash Racks

- Service Gates

- Sonar Bearings

Fluorogold® Slide Plates Bearings – Product Specifications Brochure

PTFE vs Fluorogold

Learn more about the differences between PTFE vs. Fluorogold.

Why Fluorogold® Slide Bearings?

Learn more about Fluorogold.

Fluorogold® Slide Plates

Contact us today.

Get information about Fluorogold Slide Plates.