Benefits:

Low Coefficient of Friction

Proven Product with over 50 years of service

Custom-designed to your application’s requirements

Manufactured in America

Design Data:

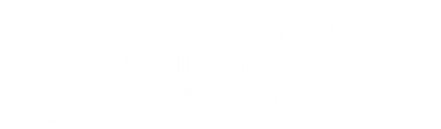

Loading Range: 75 to 3,500psi

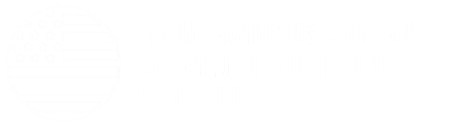

Temperature Range: -320° to +400°F

Coefficient of friction: 0.10 to 0.04 (See below)

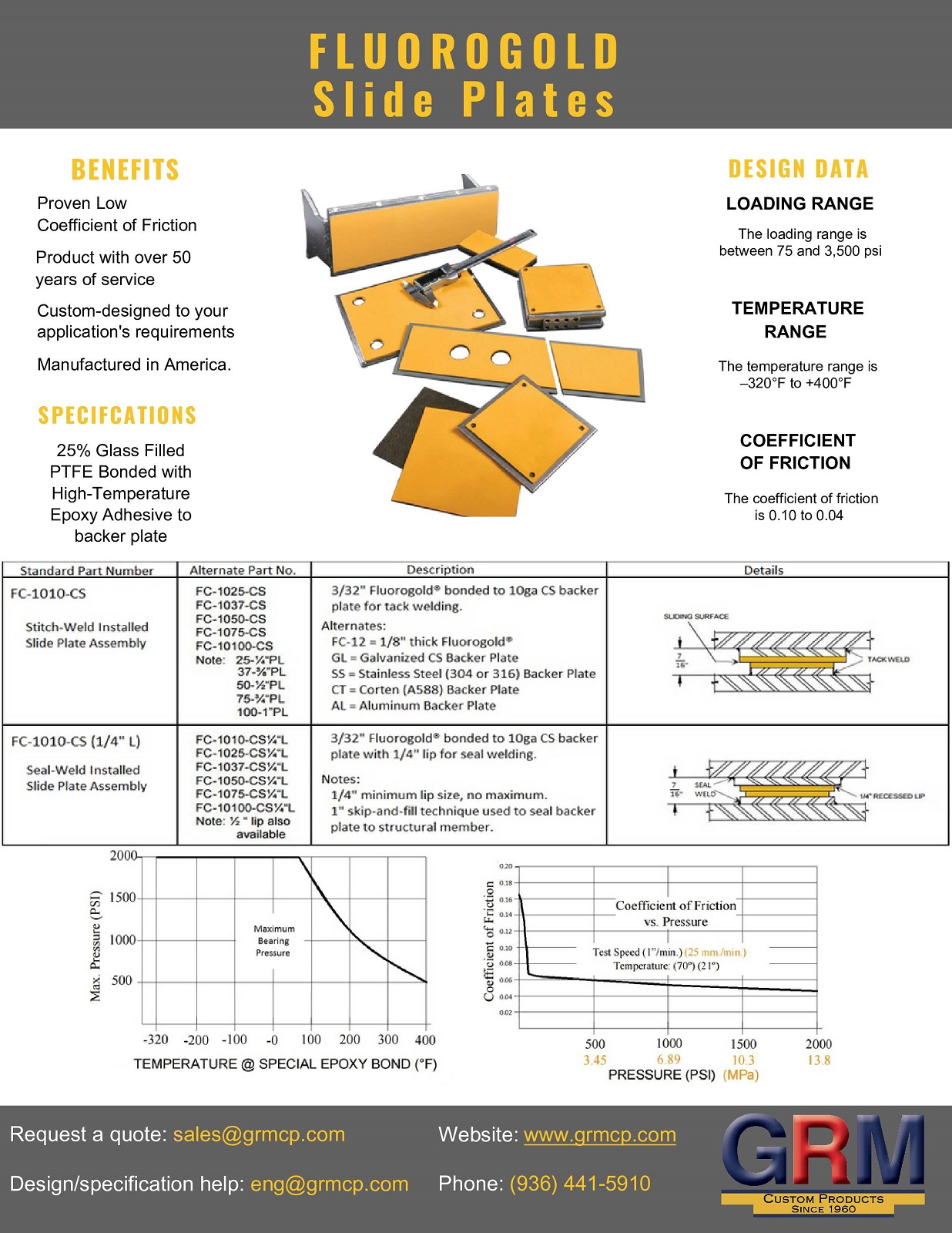

Specifications:

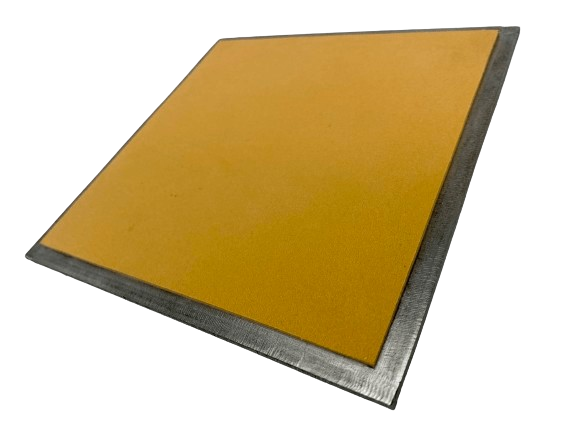

25% Glass Filled PTFE Bonded with High-Temperature Epoxy Adhesive to backer plate

Features:

FLUOROGOLD® is a premium formulation of PTFE (Teflon®) combined with special reinforcing agents to offer a high compressive strength, and is widely considered the gold standard for quality and consistency proven over time. This premium blend yields a structural material that offers significantly higher mechanical properties than PTFE itself. Compressive creep is virtually eliminated, wear is substantially reduced, and deformation is decreased. Engineered drawings will often call out FC-1010-CS. A standard FLUOROGOLD® slide plate assembly has two plate which work together (bottom and larger top) 3/32″ Teflon® machine bonded to a backer steel plate using a high heat epoxy and cured under precise heat and pressure in hydraulic presses, and can also include a lip for tack welding. GRM’s FLUOROGOLD® slide plates work to absorb the displacement of machinery and structures due to thermal expansion, wind, or seismic vibrations, making it an excellent selection for bridges, highways, buildings, retractable roof stadiums and pipelines. FLUOROGOLD® maintains a low friction coefficient across a wide temperature range, is chemically inert and self-lubricating to offer longevity and low maintenance. It is a compact solution and advantageous to engineers for easy incorporation into various designs and applications.

Fluorogold® Slide Plates – Product Specifications Brochure

PTFE vs Fluorogold

Learn more about the differences between PTFE vs. Fluorogold.

Why Fluorogold® Slide Bearings?

Learn more about Fluorogold.

Fluorogold® Slide Plates Bearings

Get information about Fluorogold Slide Plates.