What is HDPE Plastic?

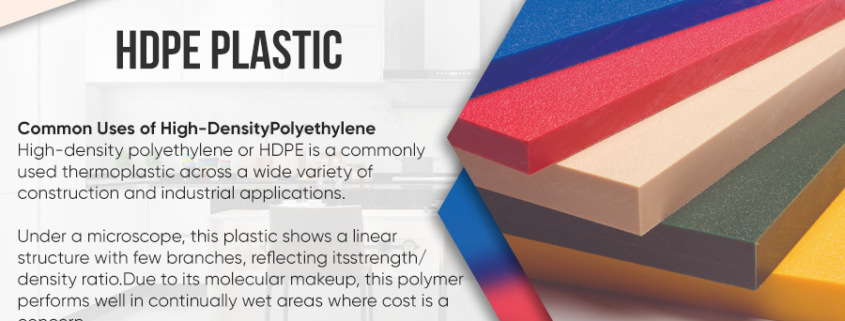

Common Uses of High-Density Polyethylene

High-density polyethylene or HDPE is a commonly used thermoplastic across a wide variety of construction and industrial applications.

Under a microscope, this plastic shows a linear structure with few branches, reflecting its strength/density ratio. Due to its molecular makeup, this polymer performs well in continually wet areas where cost is a concern.

HDPE was developed in the 1930s and used during World War II in radar cables. It can vary in flexibility with low-density grades less stiff and the high-density grades yielding a much stiffer material. It is the stiffer version that sees most use in construction applications.

Depending on your needs, HDPE is an excellent entry material choice for consideration. You can find materials that are stronger and will last longer, but with the right application, it is an excellent option.

Here are some advantages and disadvantages to consider:

Advantages of HDPE Plastic

- Can withstand temperatures from -148 to 176 degrees Fahrenheit

- Cost effective material with color additives available providing added strength.

- Cost-effective material that is UV-resistant and resistant to many chemical solvents

- Low Coefficient of Friction for use as Slide Wear Pads

Disadvantages HDPE Plastic

- Poor weathering resistance with sensitivity to cracking as it ages

- Flammable material and difficult to bond with Low Coefficient of Friction

- NOT Resistant to Chlorinated Hydrocarbons & Oxidizing Acids

4 Common Uses for HDPE

- Piping Systems

- Bearing and Slide Wear Pads

- Chemical containers, Recycling bins and Cutting boards.

- Blow-molding for water bottles and food containers, non-leaching and is a recyclable material.